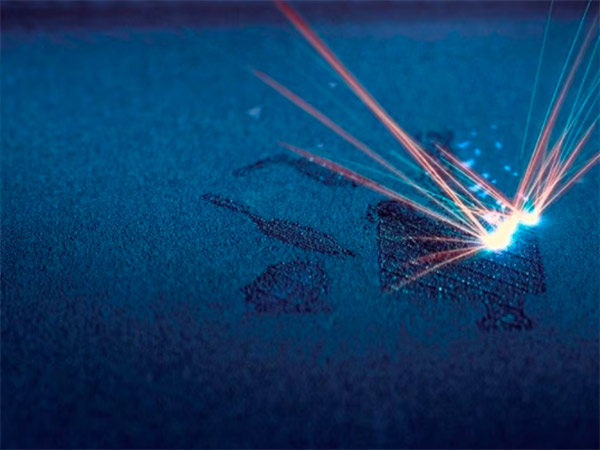

Metal Sintering

The metal sintering procedure (DMLS) is a rapid prototyping technology that is extremely useful for the creation of perfectly functional prototypes, excluding the use of additional equipment. DMLS in fact allows the creation of 3D prototypes with the same mechanical and thermal properties as elements obtained by casting.

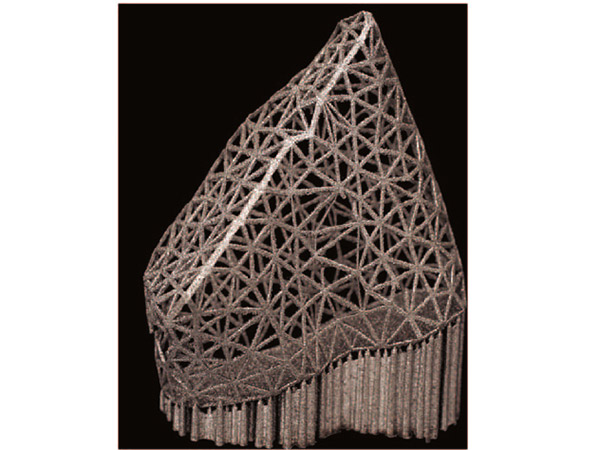

The products obtained from the use of such work processes also guarantee the achieving of high levels of finish through the application of treatments such as sandblasting, smoothing, finishing using CNC machines and lathes and other treatments intended to provide you with the required finish. It therefore represents an extremely useful process for the creation of moulds, inserts and industrial spare parts.

There are no dimensional limits as it is possible to reassemble the cut parts via welding. The maximum production area is 500x280x345 mm for monolithic parts.

Contact us to receive further information and to request a detailed quote. We will provide you with the support you require for the definition of custom models and that perfectly meet your needs and guarantee you high performance.

Materials for DMLS

Ideal applications

DMLS therefore represents a type of working that is extremely useful for the definition of perfectly functional models and components with all the technical characteristics that combine to obtain the correct functioning of the same. In particular we can state:

- Functional prototypes;

- Models with complex geometries;

- Moulds and inserts;

- Industrial spare parts;

Thermal energy is used to achieve the sintering of powders, first loose and then in aggregate form. The creation of particularly resistant prototypes ensures the elements obtained through this procedure meet the needs of the final test of the mechanical prototype, both from a thermal and actually structural point of view.

Resistance and functionality

The use of DMLS technology allows the creation of 3D prototypes that are able to effectively support the action of high temperatures and of external overloads, guaranteeing correct operation even in extreme conditions.

The products obtained through the use of such working in fact reach exceptionally high levels of performance that, combined with the attention to the individual details, allow the definition of purely functional elements.

If on the one hand, in fact, the particular resistance of such products makes them perfectly suitable for a wide variety of industrial uses, on the other, they are extremely versatile models, designed to undergo equally different treatments and finishes, depending on the work requirements.

Contact us to receive further information and to use the consultancy of our team. We will provide you with the assistance you require.